Industrial Coffee Mill Guide: Increase Effectiveness and Quality

In the competitive landscape of coffee manufacturing, selecting the right commercial coffee mill plays a crucial duty in boosting both performance and item top quality. Comprehending the subtleties of numerous mill kinds and essential functions-- such as adjustable grind settings and robust building and construction-- can significantly influence the last flavor account of the coffee. The optimization of the grinding procedure, coupled with diligent upkeep, is necessary for sustaining performance over time. As we discover these crucial aspects, it becomes apparent that the effects expand beyond plain tools selection, influencing overall business success in manner ins which necessitate closer assessment.

Comprehending Mill Types

When choosing an industrial coffee mill, recognizing the various kinds available is critical for optimizing both flavor removal and functional performance. The two key kinds of grinders are blade grinders and burr mills.

Eventually, choosing the ideal kind of mill is important to maintaining top quality and effectiveness in coffee manufacturing, making it important for services to buy top quality burr grinders for optimal outcomes.

Key Features to Take Into Consideration

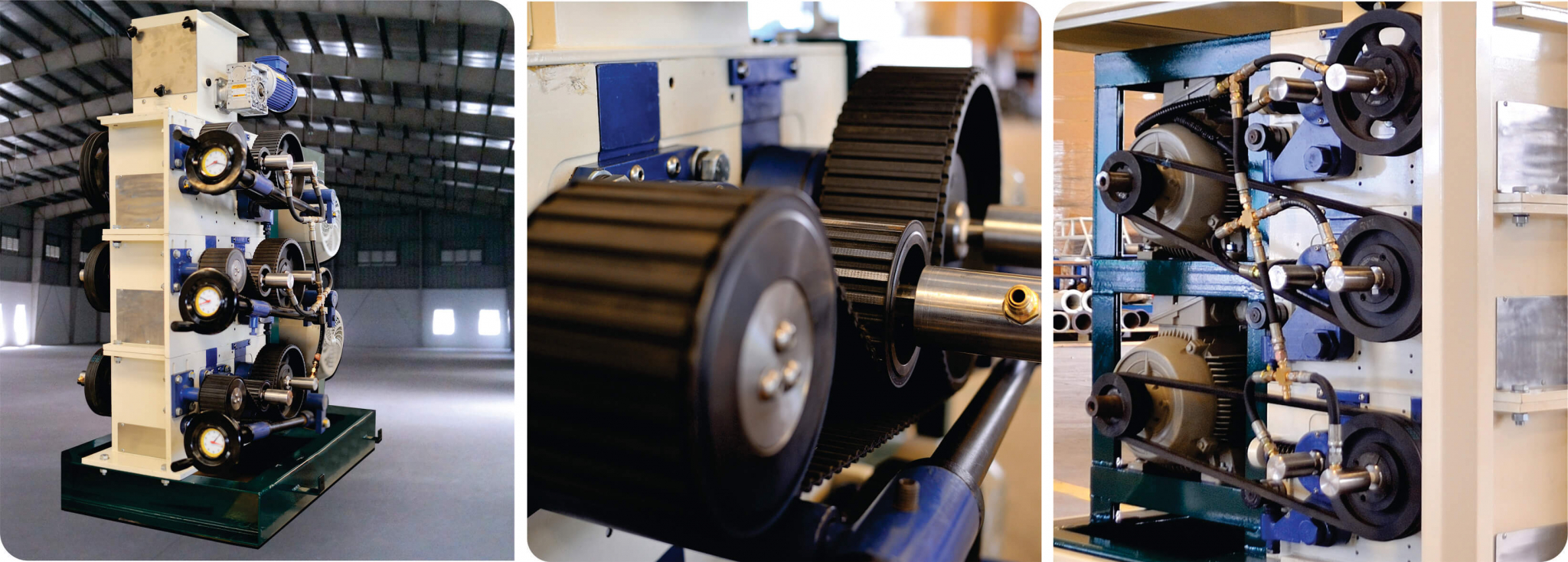

Selecting an industrial coffee mill calls for cautious consideration of a number of vital features that can considerably affect both efficiency and the general coffee experience. Among the main aspects to evaluate is the grinding device. Burr mills are usually preferred over blade mills, as they give a constant work dimension, which is important for ideal removal and taste.

One more essential attribute is the grinder's capability. A flexible grinder with multiple settings enables you to customize the grind dimension to different brewing approaches, improving the coffee's taste account.

Examine the mill's sound level, particularly in a busy café or manufacturing setting, where too much sound can be turbulent. Investing in a mill that balances these features can considerably enhance both functional efficiency and the high quality of the coffee offered.

Optimizing Grinding Process

To achieve the very best lead to coffee preparation, maximizing the grinding process is essential. The grind dimension significantly influences removal, flavor, and total quality of the made coffee. Different developing methods need particular grind sizes; for example, coffee demands a fine grind, while French press necessitates a coarse texture. Comprehending the connection in between grind size and developing technique is the primary step in optimization.

In addition, keeping track of the grinding rate can maximize the process. Slower grinding usually creates less warmth, protecting fragile tastes and scents. On the other hand, much faster grinding might produce excessive warmth, negatively influencing the coffee's high quality.

Upkeep and Care Tips

Appropriate upkeep and care of industrial coffee grinders are important for making certain ideal efficiency and durability. Regular cleansing is the foundation of upkeep; deposit build-up can influence flavor and grinding performance. It is suggested to clean up the mill after each use, wiping down the exterior and removing any kind of coffee premises from the burrs.

In addition, evaluate the grinding burrs for damage. Plain burrs look these up can endanger grind consistency, so they ought to be replaced as essential. Industrial Coffee Grinder. Occasionally calibrating the mill is additionally crucial, as this preserves the desired grind size for different developing approaches

Lubrication of relocating components ought to be executed according to the producer's specs, as this reduces friction and lengthens the life of the devices. It is crucial to use food-grade lubes to ensure safety and security and conformity with health and wellness guidelines.

Finally, maintain the mill in a steady and dry environment to stop rust and rust. By adhering to these upkeep and care suggestions, drivers can boost the efficiency of their industrial coffee grinders while making certain top quality output and prolonged functional life.

Roi Evaluation

Reviewing the return on financial investment (ROI) for commercial coffee grinders is important for companies looking for to enhance their coffee production capacities. A comprehensive ROI evaluation aids figure out the economic stability of investing in high-grade mills, allowing companies to weigh the initial costs versus potential gains.

To perform a comprehensive ROI evaluation, companies should take into consideration several essential factors. Assess the acquisition cost of the grinder, consisting of installation and any type of necessary alterations to existing infrastructure. Next off, compute functional expenses, including energy usage, upkeep expenditures, and labor effectiveness renovations. High-performance mills commonly lead to decreased grinding time and raised throughput, which can significantly improve performance.

Furthermore, consider the effect on item top quality. Industrial Coffee Grinder. Superior mills yield an even more constant work dimension, which can enhance taste accounts and client complete satisfaction, inevitably driving sales. By increasing the high quality of the final product, organizations can justify find greater pricing, resulting check my source in raised revenue

Verdict

In recap, a commercial coffee mill plays a crucial duty in improving both efficiency and item high quality within coffee production. By selecting premium burr grinders outfitted with essential features such as adjustable grind setups and sturdy building and construction, companies can guarantee optimum flavor extraction. Normal upkeep is crucial for maintaining mill efficiency and optimizing client contentment. Ultimately, the calculated financial investment in a dependable mill contributes substantially to enhanced profits and competitiveness in the coffee market.

In the affordable landscape of coffee manufacturing, selecting the ideal commercial coffee grinder plays a crucial duty in boosting both effectiveness and product top quality. The two primary kinds of grinders are blade grinders and burr mills. Within the burr grinder category, there are flat burr mills and conical burr grinders, each with its benefits. Burr mills are typically preferred over blade mills, as they supply a regular work dimension, which is vital for optimum removal and flavor.

In summary, a commercial coffee grinder plays an essential role in enhancing both effectiveness and item quality within coffee manufacturing.